|

|

||

|

See the latest in artificial lift controls at our booth in Lubbock. |

||

|

|

||

|

Try the new on-line tool for predicting fluid properties. |

||

|

|

||

|

Keep your SRPs healthy with the new automated valve-checking feature. |

||

|

|

||

|

Learn the latest improvements in our SRP software. |

||

|

|

||

|

Watch for these topics in upcoming issues. |

||

| Printer-Friendly Version | |

| Send to a Friend | |

| · Subscribe | |

| · Unsubscribe | |

![]()

| · Issue 13 | · Issue 6 |

| · Issue 12 | · Issue 5 |

| · Issue 11 | · Issue 4 |

| · Issue 10 | · Issue 3 |

| · Issue 9 | · Issue 2 |

| · Issue 8 | · Issue 1 |

| · Issue 7 |

![]()

Oil & Gas Automation

Solutions is a publication

of Unico, Inc.

Unico, Inc.

3725 Nicholson Rd.

P. O. Box 0505

Franksville, WI

53126-0505

262.886.5678

262.504.7396 fax

oilgas@unicous.com

unicous.com

Copyright © 2005

Unico, Inc.

All rights reserved.

All trade designations

are provided without

reference to the rights of

their respective owners.

Unico to Exhibit at the Southwest Petroleum Short Course April 20-21

With this issue, Unico debuts its Correlations Calculator, a convenient tool for predicting the fluid properties of a well from limited information.Measurements of the physical properties of a fluid are essential to reservoir and production engineering. To perform their calculations, petroleum engineers need to know a fluid's viscosity, density, dissolved gas content, and other factors, as well as how these properties vary with temperature and pressure.Such information, however, is not usually readily available. In the early stages of a well it can be difficult or economically impractical to obtain reliable measurements. Fluid samples, if available, can be subjected to pressure-volume-temperature analyses to determine their properties, but samples are often suspect and PVT analyses usually apply only at reservoir temperature.One solution is to use what are known as correlations. By studying field data and fitting curves to measured results, engineers have developed empirical relationships that relate various fluid properties. These correlations are useful tools for estimating fluid properties from limited information. A variety of methods have been developed and published in the literature over the years that produce varying degrees of success depending upon the application.

Correlations can be grouped into two basic categories—those that assess gas content and those that predict viscosity. Correlations in the first group are helpful in estimating the amount of gas dissolved in the fluid and at what pressure that gas will evolve. They also estimate the influence of gas on fluid volume and density. Correlations in the second group predict the viscosity of the fluid for gas-free or "dead" oil, saturated oil, and undersaturated oil. We will be introducing various correlation methods from both categories in upcoming issues of Solutions. The first two correlations we'd like to examine are the Standing and Beal methods. Standing's Correlation

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

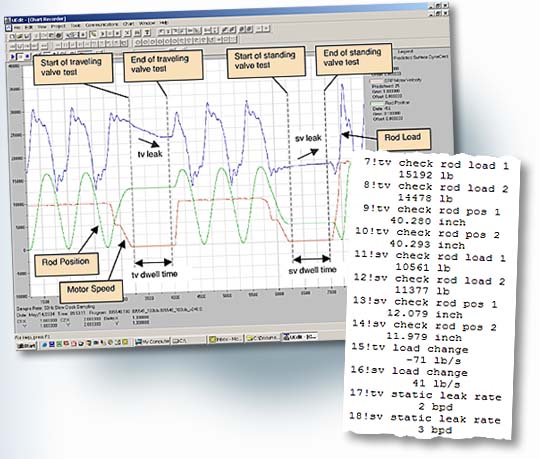

The valve check feature gives users the ability to closely monitor the health of their pumps and to quickly identify and repair pump problems. Since valve checks can be done frequently, failures can be detected early to eliminate the costly loss of production and wasted power consumption associated with operating worn or broken pumps. A valve check can be initiated either from the drive's keypad or remotely over a communication link. For added convenience, a software option allows the test to be scheduled automatically at a preset time each day. Head-end well management software can also be programmed to automatically display the results of the valve checks as well as an alert message if pump leakage exceeds a threshold value. The valve-check feature is yet another example of how Unico's innovation helps you get the most from your artificial lift systems. For more information on the feature, stop by booths #34 and #35 at the SWPSC show or contact us. Numerous Feature Improvements in Recent Releases of Unico's Sucker-Rod Pump (SRP) Control Software

|

|||||||||||||||||||||||||||||||||||||||||||||||||

| Version .106 Improvements | |

| Added automated valve check (see article above) | |

| Added automatic daily production gauging (production recording) | |

| Added last valve check time and date stamp | |

| Added automatic pump clearance identification (during valve check) | |

| Added automatic pump fill trigger determination (determined every stroke) | |

| Added user SPM adjustment | |

| Added a well ID progress bar display | |

| Added analog tubing pressure input support | |

| Added analog casing pressure input support | |

| Added motor peak power monitor and display | |

| Added a cold start current limiter | |

| Added storage of the four latest surface dynamometer cards | |

| Improved the well ID routine for compatibility with gas-powered generator systems | |

| Improved the well ID routine compatibility with HG pump jacks | |

| Improved the well ID routine for symmetrical pumping units | |

| Improved the “calibrate inclinometer” signal | |

| Improved the “counterbalance assist” signal | |

| Improved the gearbox torque limiting (torque limit) | |

In Future Issues...

Look for the following articles in upcoming issues of Oil & Gas Automation Solutions:

| Field tests of methods to eliminate rod pump gas locking and interference | |

| Reducing power consumption and improving power factor of beam pumps | |

| Using a torque economizer mode to improve efficiency and reduce gearbox stress | |

| Detecting stick/slip oscillations that fatigue rod-string couplings and reduce energy efficiency of PCPs | |

| Control options to ride through power disturbances |

Unico will once again be showcasing its innovative artificial lift controls at the 52nd annual

Unico will once again be showcasing its innovative artificial lift controls at the 52nd annual  be featured include our sophisticated sucker-rod (SRP), progressing cavity (PCP), and electric submersible (ESP) pump controllers, our new natural gas-powered artificial lift system, remote communication options, and much more. This is our second year at the Short Course, and last year we had a great response. Visit us at booths #34 and #35 to see what sets us apart from the rest. For further information, please

be featured include our sophisticated sucker-rod (SRP), progressing cavity (PCP), and electric submersible (ESP) pump controllers, our new natural gas-powered artificial lift system, remote communication options, and much more. This is our second year at the Short Course, and last year we had a great response. Visit us at booths #34 and #35 to see what sets us apart from the rest. For further information, please