![]()

| · Welcome! | |

| · Multispeed option | |

| · Cost-effective lift drives | |

| · Balancing a pump | |

| · In future issues | |

| Printer-Friendly Version | |

| Send to a Friend | |

| · Subscribe | |

| · Unsubscribe | |

![]()

Oil & Gas Automation

Solutions is a publication

of Unico, Inc.

Unico, Inc.

3725 Nicholson Rd.

P. O. Box 0505

Franksville, WI

53126-0505

262.886.5678

262.504.7396 fax

oilgas@unicous.com

unicous.com

Copyright © 2002

Unico, Inc.

All rights reserved.

All trade designations

are provided without

reference to the rights of

their respective owners.

Welcome to Oil & Gas Automation Solutions, Our E-Newsletter

Welcome to Oil & Gas Automation Solutions, Our E-Newsletter

Welcome to the inaugural issue of Oil & Gas Automation Solutions, an email publication of Unico, Inc. Solutions was created to keep you informed of fresh approaches to exploration and production. We think you'll find it useful.

While this newsletter is new to the industry, our company is not. For more than a decade, we've been innovating solutions to the control challenges of oil and gas fields worldwide. Over the years, we've evolved drive systems specifically for oil and gas applications. Today, thousands of our drives are performing from the tropics to the arctic, from high-power drill-rig mud pumps, top drives, and draw works used in exploration to uniquely designed artificial-lift drives for progressive cavity pumps (PCPs), electric submersible pumps (ESPs), and the various types of rod pumps. Our practical field experience ranges from small coal-bed methane dewatering pumps to large heavy-oil submersibles.

We've come to realize that much of what we've learned has great potential for improving operations and reducing cost, and that many operators may be unaware of this potential. Our goal for this publication is to help operators understand the shifting technology that can benefit their bottom line while creating a dialog with the user community that fosters continuing evolution of that technology.

Solutions will...

| Discuss technical issues and practical techniques for improvement that may not be obvious to all operators | |

| Describe individual product features, how to apply them, and the benefits they provide | |

| Introduce new product innovations and enhancements | |

| Demonstrate real-world benefits with actual case studies | |

| Alert you to changes in technology that could pose a threat or opportunity for the industry | |

| ...and much more |

As Solutions grows, your input is vital. We are committed to making it both useful and interesting, so please feel free to send suggestions or comments. After all, this is really your newsletter. We hope you’ll enjoy it.

Balancing a Pumping Unit with Motor Torque Instead of Motor Current

Balancing a Pumping Unit with Motor Torque Instead of Motor Current

by Ron Peterson research & development engineer

Beam style sucker-rod pumping units are typically counterbalanced using a technique of matching upstroke and downstroke motor currents. A clamp-on current probe is connected to a portable digital voltmeter (DVM), and motor current is monitored as the counterweights are adjusted. When the upstroke and downstroke current values balance, the pumping unit is considered mechanically balanced.

This method of balancing a pumping unit is effective when the unit is already close to proper balance, however, it may otherwise result in a grossly unbalanced condition. Since the DVM cannot detect whether the AC current is leading or lagging the voltage, the DVM motor current will indicate a positive value, regardless of whether the motor is regenerating or motoring. Regenerative currents, therefore, may be mistaken for motoring currents. The result may be a severely unbalanced pumping unit.

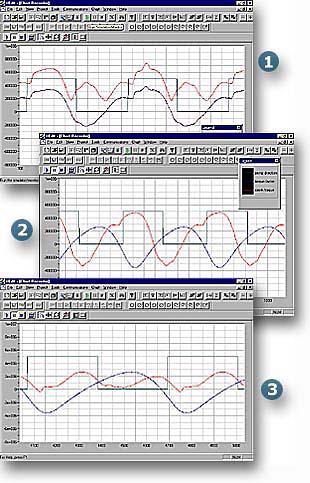

An alternate method of balancing the pumping unit is to compare upstroke and downstroke motor torque values. The motor torque signal does not suffer from the phase-orientation problem of motor current. See Figure 1. The red trace is motor current, and the blue trace is motor torque. While the motor current signal indicates positive values for both upstroke and downstroke, the motor torque signal reveals the negative torque during the upstroke. The pumping unit is severely overbalanced.

Figure 2 shows motor torque (red) and torque factor (blue) for the same overbalanced well.

After balancing the pumping unit (Figure 3), the upstroke and downstroke motor torque peaks are balanced, and the torque peak values are dramatically reduced. The resulting reduction in RMS torque and dynamic braking contribute to less input power consumption.

![]() Contact us for further details

Contact us for further details

Cost-Effective 1105 Series Drives Introduced for Small Artificial-Lift Systems

The new 1105 Series drives can be a cost-effective method of driving small ESP, PCP, and rod pumps. Power ratings from 2 to 40 hp are particularly useful for coal-bed methane (CBM) and stripper well production. Self-contained units that include a pump-off control, selector switches, and electrical disconnect are suitable for outdoor environments. The units also include a dynamic braking option to maintain control of rod pump speed on both the up and down strokes. The rod pump unit provides pump-off control and dynacard generation without the need for an external position sensor or load cell. ESP and PCP units include options for the control of fluid level and optimization of gas flow in CBM applications.

The new 1105 Series drives can be a cost-effective method of driving small ESP, PCP, and rod pumps. Power ratings from 2 to 40 hp are particularly useful for coal-bed methane (CBM) and stripper well production. Self-contained units that include a pump-off control, selector switches, and electrical disconnect are suitable for outdoor environments. The units also include a dynamic braking option to maintain control of rod pump speed on both the up and down strokes. The rod pump unit provides pump-off control and dynacard generation without the need for an external position sensor or load cell. ESP and PCP units include options for the control of fluid level and optimization of gas flow in CBM applications.

Multispeed Option Improves Artificial Lift Performance

Unico artificial-lift drives incorporate a multiple speed selector to improve the performance of rod pumping systems. Many pump jacks are operated at a fixed speed for a variable on/off period to maintain pump fill. The Unico single-speed mode allows the pump to be run at a continuous speed selected to match well inflow without having to cycle the pump. A dual-speed mode provides independent up and down speeds to optimize production without overstressing the rod on the upstroke or allowing it to float on the downstroke. A triple-speed mode provides independent up, down, and cornering speeds for Rotaflex pumps. Rotaflex average speed can be increased from 4.5 to 6.0 spm by increasing the straight-away speeds while limiting the cornering speeds. All speeds in the various modes can either be entered as preset values through a keypad, adjusted by means of potentiometers, set remotely through a serial communication channel, or adjusted automatically to maintain a selected fluid level or pump fill.

|

MULTISPEED OPTION... at a glance

|

|

|

|

Benefits |

|

·

|

Optimizes well production of rod pumping systems |

|

·

|

Eliminates fluid pound |

|

·

|

Reduces upstroke rod stress |

|

·

|

Eliminates downstroke rod stress |

|

|

Modes |

|

·

|

Single speed |

|

·

|

Dual speed |

|

·

|

Triple speed |

|

|

Sources |

|

·

|

Keypad preset |

|

·

|

Analog potentiometer |

|

·

|

Serial communication |

|

·

|

Fluid level control |

|

·

|

Pump fill control |

In Future Issues...

Look for the following articles in upcoming issues of Oil & Gas Automation Solutions:

| Unico DriveLink™ software enhanced to display dynagraphs and circle charts | |

| Using harmonic filters to comply with utility power quality requirements | |

| A comparison of the energy efficiency of various types of artificial lift systems |