TECHNICALLY SPEAKING:

Cost-Effective Electrical Harmonic Reduction

Cost-Effective Electrical Harmonic Reduction

by Jim Lousier hardware development manager

Electronic variable-speed drives have made a major contribution to the electrical efficiency of oil and gas production. However, the increased popularity of electronic drives has contributed to a form of electrical power-line pollution called harmonics.

Harmonic currents are those that deviate from a pure sine wave. They are generally expressed as a percentage of the fundamental current or as a distortion power factor. The percentage of harmonic current is generally referred to as Total Harmonic Distortion (THD).

High harmonic currents cause unfavorable distortion power factor, poor energy efficiency, and voltage distortion that may affect other equipment. Electrical utilities and users of electrical power are becoming increasingly concerned over harmonic issues. That concern is often expressed as a requirement to meet harmonic limits, such as those prescribed in the IEEE 519 standard.

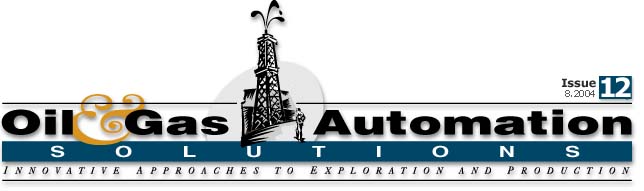

A properly designed variable-speed drive system can minimize harmonic pollution and maximize overall energy efficiency. The current traces below illustrate the nature of the harmonic problem and cost-effective remedies to eliminate that problem.

Basic variable-speed drives rectify fixed-frequency (50 or 60 Hz) line power into a DC bus voltage. Using a process called pulse width modulation (PWM), the bus voltage is converted into variable-frequency, variable-voltage power for controlling AC motors. Variable-speed drives, in this basic form, create substantial harmonic distortion in the shape of "rabbit ears."

Many manufacturers of variable-speed drives have added a link choke in the DC bus to reduce harmonic distortion by smoothing out the "rabbit ears." The configuration is sometimes referred to as a six-pulse drive based upon the nature of the three-phase rectification process.

A few manufacturers, including Unico, offer 12-pulse drives that provide an additional reduction in harmonics by providing more sinusoidally shaped currents. This type of drive can use a delta wye transfomer of half the total drive capacity and a small balance reactor to achieve a considerable reduction in harmonics.

This configuration also has the benefit of higher limits under the IEEE 519 standard. The IEEE 519 standard prescribes maximum harmonic current limits that are based on the softness of the power line. That softness is defined as the ratio of the line short-circuit current to rated line current. In other words, the greater the short-circuit current relative to the rated capacity, the stiffer the power line.

The 12-pulse drive provides a nearly sine-wave-shaped input current compared to a six-pulse drive. The IEEE 519 standard recognizes this improved waveform by allowing higher harmonic limits for 12-pulse versus six-pulse configurations.

Six-Pulse Drive Harmonic Limits

IEEE 519 Standard

| Short-Circuit Ratio |

Total

Demand Distortion |

5th

|

7th

|

11th

|

13th

|

17th

|

19th

|

|

| < 20 |

5.0

|

4.0

|

4.0

|

2.0

|

2.0

|

1.5

|

1.5

|

|

| 20 < 50 |

8.0

|

7.0

|

7.0

|

3.5

|

3.5

|

2.5

|

2.5

|

|

| 50 < 100 |

12.0

|

10.0

|

10.0

|

4.5

|

4.5

|

4.0

|

4.0

|

|

| 100 < 1000 |

15.0

|

12.0

|

12.0

|

5.5

|

5.5

|

5.0

|

5.0

|

|

| > 1000 |

20.0

|

15.0

|

15.0

|

7.0

|

7.0

|

6.0

|

6.0

|

12-Pulse Drive Harmonic Limits

IEEE 519 Standard

| Short-Circuit Ratio |

Total

Demand Distortion |

5th

|

7th

|

11th

|

13th

|

17th

|

19th

|

|

| < 20 |

5.0

|

1.0

|

1.0

|

2.8

|

2.8

|

0.4

|

0.4

|

|

| 20 < 50 |

8.0

|

1.8

|

1.8

|

4.9

|

4.9

|

0.6

|

0.6

|

|

| 50 < 100 |

12.0

|

2.5

|

2.5

|

6.4

|

6.4

|

1.0

|

1.0

|

|

| 100 < 1000 |

15.0

|

3.0

|

3.0

|

7.8

|

7.8

|

1.3

|

1.3

|

|

| > 1000 |

20.0

|

3.8

|

3.8

|

9.9

|

9.9

|

1.5

|

1.5

|

Harmonics generally are multiples of the power line frequency (5th, 7th, and so forth) with amplitudes that depend upon the pulse number of the drive. The IEEE 519 standard specifies limits on individual harmonic components as well as Total Demand Distortion (TDD) as a percentage of maximum load demand current.

To learn more about reducing harmonics, please contact us.

PRODUCT WATCH:

New Graphic Display Shows DynaCards and More

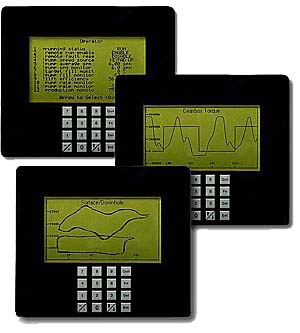

A new graphic display option adds the power of visualization to Unico drives. The 2.25" by 4.25" liquid crystal display presents data in a variety of graphical and textual formats that bring to life the sophisticated information available within Unico artificial-lift drives. With the graphic display, users can view simultaneous surface and downhole dynamometer graphs or other XY plots right at the drive. Time-based data, such as gearbox torque or trend lines, can be displayed in a strip chart showing up to four parameters at a time. An easy-to-read text menu format shows up to a dozen parameters at once and makes setting up and monitoring the drive a breeze. For more information on the graphic display, please contact us.

A new graphic display option adds the power of visualization to Unico drives. The 2.25" by 4.25" liquid crystal display presents data in a variety of graphical and textual formats that bring to life the sophisticated information available within Unico artificial-lift drives. With the graphic display, users can view simultaneous surface and downhole dynamometer graphs or other XY plots right at the drive. Time-based data, such as gearbox torque or trend lines, can be displayed in a strip chart showing up to four parameters at a time. An easy-to-read text menu format shows up to a dozen parameters at once and makes setting up and monitoring the drive a breeze. For more information on the graphic display, please contact us.

Bluetooth Wireless Link Simplifies Data Collection

Would you like to capture well data from the comfort and security of your truck? With a Bluetooth wireless link, you can do just that.

Would you like to capture well data from the comfort and security of your truck? With a Bluetooth wireless link, you can do just that.

Bluetooth is a wireless communication technology that connects devices within up to 300 feet, depending upon the power class selected. It is readily available for both handhelds and personal computers, meaning you can use your laptop or PDA without having to get out, walk up to the drive cabinet, and make a physical connection. It eliminates all of the connectivity issues and cumbersome cabling as well.

| Input Parameter |

Value

|

Results | Value | |

| Fluid Density (psi/ft) |

0.433

|

Linear Average Flow (bpd) | 1006 | |

| Casing Diameter (in) |

5.000

|

Linear Lost Production (%) | 16.2 | |

| Tubing Diameter (in) |

2.875

|

Vogel Average Flow (bpd) | 1079 | |

| Reservoir Static Head (ft) |

2000

|

Vogel Lost Production (%) | 10.1 | |

| Reservoir Maximum Flow (bpd) |

1200

|

|||

| Pump Stop Head (ft) |

0

|

|||

| Pump Output Flow (bpd) |

1500

|

|||

| Pump Off Time (s) |

1000

|

Unico offers a suite of software for personal computers and PDAs for archiving data and events, charting, and remote setup and monitoring. Combined with a Bluetooth wireless link, these tools provide a convenient and efficient method of gathering well information and diagnosing well problems.

Unico offers a suite of software for personal computers and PDAs for archiving data and events, charting, and remote setup and monitoring. Combined with a Bluetooth wireless link, these tools provide a convenient and efficient method of gathering well information and diagnosing well problems.

WHAT'S COMING UP:

In Future Issues...

Look for the following articles in upcoming issues of Oil & Gas Automation Solutions:

| Field tests of methods to eliminate rod pump gas locking and interference | |

| Reducing power consumption and improving power factor of beam pumps | |

| Using a torque economizer mode to improve efficiency and reduce gearbox stress | |

| Detecting stick/slip oscillations that fatigue rod-string couplings and reduce energy efficiency of PCPs |

Oil & Gas Automation Solutions is a publication of Unico, Inc. Copyright © 2003 Unico, Inc. All rights reserved.

All trade designations are provided without reference to the rights of their respective owners.

![]() Unico, Inc., 3725 Nicholson Rd., P. O. Box 0505, Franksville, WI 53126-0505

Unico, Inc., 3725 Nicholson Rd., P. O. Box 0505, Franksville, WI 53126-0505

262.886.5678 / 262.504.7396 fax

oilgas@unicous.com / unicous.com