Unico will be exhibiting a number of its new products at the Southwest Petroleum Short Course in Lubbock, Texas, on April 21-22 and at the Four-Corners Oil and Gas Conference in Farmington, New Mexico, on May 12-13. Products to be showcased include our sophisticated sucker-rod (SRP), progressing

Unico will be exhibiting a number of its new products at the Southwest Petroleum Short Course in Lubbock, Texas, on April 21-22 and at the Four-Corners Oil and Gas Conference in Farmington, New Mexico, on May 12-13. Products to be showcased include our sophisticated sucker-rod (SRP), progressing cavity (PCP), and electric submersible (ESP) controllers with enhanced features, our new variable-voltage drive, the Unico Well Monitor, remote communications options, and much more. We hope to see you there.

cavity (PCP), and electric submersible (ESP) controllers with enhanced features, our new variable-voltage drive, the Unico Well Monitor, remote communications options, and much more. We hope to see you there.

TECHNICALLY SPEAKING:

Taking Advantage of Utility Rate Structures to Reduce Artificial-Lift Energy Costs

Taking Advantage of Utility Rate Structures to Reduce Artificial-Lift Energy Costs

by Russ Tennessen oil and gas account manager

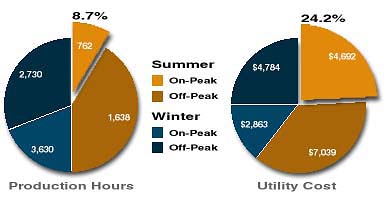

Most utility districts offer some type of time-of-use rate structure to encourage a more efficient use of their energy-delivery system. Those rate structures are designed to shift demand from periods of high peak load to periods of light loads. Southern states, in particular, experience heavy midday loads from air conditioning that, at their worst, can cause brownouts. In those areas, there can be as much as a three-to-one difference between on-peak and off-peak energy costs. Oil and gas producers with these types of rate structures can dramatically reduce their energy costs by reducing artificial-lift operations during on-peak periods.

Since on-peak periods are only a few hours of each normal workday, little productive capacity is lost by stopping operations during those periods. The following example is based on a 50 hp pump jack operating on the E-37 Oil and Gas utility rates of Pacific Gas and Electric (PG&E).

Summer and Winter Utility Rates (PG&E)

E-37 Oil and Gas Extraction

| Rate |

Summer

|

Winter

|

|

| On-Peak Energy ($/kWh) |

$0.14294

|

$0.04661

|

|

| Off-Peak Energy ($/kWh) |

$0.04088

|

$0.03706

|

|

| On-Peak Demand ($/kW/month) |

$2.70

|

$0.00

|

|

| Maximum Demand ($/kW/month) |

$6.55

|

$4.40

|

Distribution of Utility Cost vs. Production Hours

In this case, the operator could give up 762 hours of peak summer operation or 8.7% of the total available hours and save $4,692 per year or 24.2% of his utility bill.

Unico artificial-lift drives incorporate a time-of-use control that facilitates these kinds of savings. For more information, please contact us.

TRADE SHOWS:

Unico to Exhibit at the Southwest Petroleum Short Course and Four-Corners

Oil Show

PRODUCT WATCH:

New Inclinometer Provides Beam Angle and Acceleration in a Compact Package

Unico is introducing a cost-effective inclinometer that measures beam angle and acceleration for about the price of a proximity switch. The compact, weatherproof unit mounts easily to a pump-jack beam and provides ±30° beam angle measurement, a 0° crossing logic signal, and beam acceleration measurement. Rod position can be determined directly from beam angle or indirectly from pumping-unit geometry, beam zero crossing, and motor rotation. Beam acceleration is useful for diagnostics and for improving the dynamic regulation of the rod-stroking motion. For information on the inclinometer and its use in rod-pumping applications, please contact us.

Unico is introducing a cost-effective inclinometer that measures beam angle and acceleration for about the price of a proximity switch. The compact, weatherproof unit mounts easily to a pump-jack beam and provides ±30° beam angle measurement, a 0° crossing logic signal, and beam acceleration measurement. Rod position can be determined directly from beam angle or indirectly from pumping-unit geometry, beam zero crossing, and motor rotation. Beam acceleration is useful for diagnostics and for improving the dynamic regulation of the rod-stroking motion. For information on the inclinometer and its use in rod-pumping applications, please contact us.

PERFORMANCE ANALYSIS TOOL:

New Pump-Off Control (POC) Calculator Estimates Lost Production

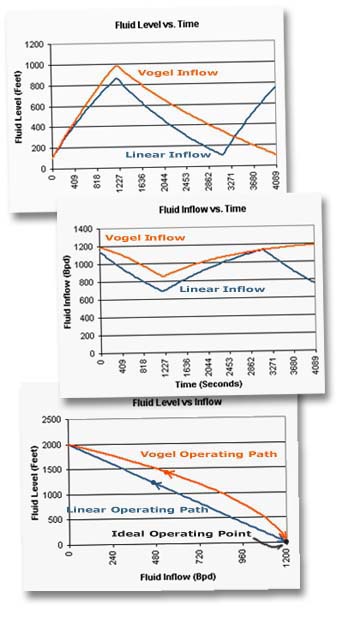

Most rod-pumping units use some form of pump-off control (POC) to regulate production and maintain fluid in the well casing. The on/off duty cycle may be manually or automatically adjusted. A typical sequence runs a rod pump for a period of time to pull fluid from the well, which pulls down the fluid level in the casing. Eventually the fluid level will be drawn down to the pump intake and  the pump will exhibit a pump-off condition. Automatic pump-off controllers will detect this condition and pause the pumping operation for a period of time. During this period of time, the fluid level rises in the casing.

the pump will exhibit a pump-off condition. Automatic pump-off controllers will detect this condition and pause the pumping operation for a period of time. During this period of time, the fluid level rises in the casing.

Well inflow is a function of the fluid level in the well. The fluctuating level of fluid due to the pump-off control operation increases the average fluid height in the well and reduces its average inflow. Well production is dependent upon the average inflow, which can be significantly reduced at long pump cycle times.

Unico now provides an online POC Calculator™ to evaluate the effect of pump-off control settings on well production. The calculator supports both linear and Vogel inflow characteristics. The table below and charts at left illustrate the substantial loss of production for a typical set of well parameters.

These losses can be virtually eliminated with the use of a variable-speed drive. The bottom chart shows the operating paths for linear and Vogel characteristics during the pump on/off cycle. Unico variable-speed drives maximize well production by maintaining fluid level at the ideal operating point.

Try the POC Calculator™ at http://www.unicous.com/oilgas/poccalc.php.

Example POC Calculation

| Input Parameter |

Value

|

Results | Value | |

| Fluid Density (psi/ft) |

0.433

|

Linear Average Flow (bpd) | 1006 | |

| Casing Diameter (in) |

5.000

|

Linear Lost Production (%) | 16.2 | |

| Tubing Diameter (in) |

2.875

|

Vogel Average Flow (bpd) | 1079 | |

| Reservoir Static Head (ft) |

2000

|

Vogel Lost Production (%) | 10.1 | |

| Reservoir Maximum Flow (bpd) |

1200

|

|||

| Pump Stop Head (ft) |

0

|

|||

| Pump Output Flow (bpd) |

1500

|

|||

| Pump Off Time (s) |

1000

|

WHAT'S COMING UP:

In Future Issues...

Look for the following articles in upcoming issues of Oil & Gas Automation Solutions:

| Using a torque economizer mode to improve efficiency and reduce gearbox stress | |

| Reducing power consumption and improving power factor of beam pumps | |

| Field tests of methods to eliminate rod pump gas locking and interference | |

| Detecting stick/slip oscillations that fatigue rod-string couplings and reduce energy efficiency of PCPs |

Oil & Gas Automation Solutions is a publication of Unico, Inc. Copyright © 2003 Unico, Inc. All rights reserved.

All trade designations are provided without reference to the rights of their respective owners.

![]() Unico, Inc., 3725 Nicholson Rd., P. O. Box 0505, Franksville, WI 53126-0505

Unico, Inc., 3725 Nicholson Rd., P. O. Box 0505, Franksville, WI 53126-0505

262.886.5678 / 262.504.7396 fax

oilgas@unicous.com / unicous.com